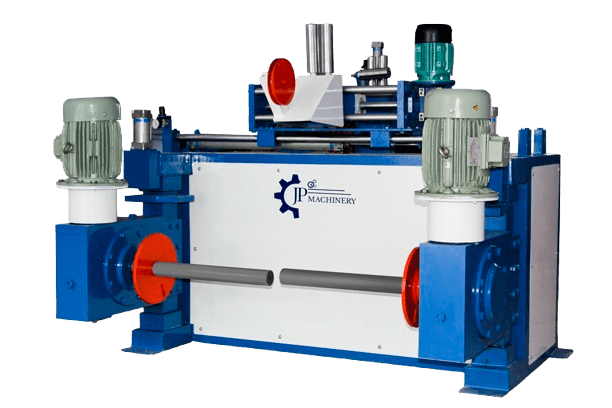

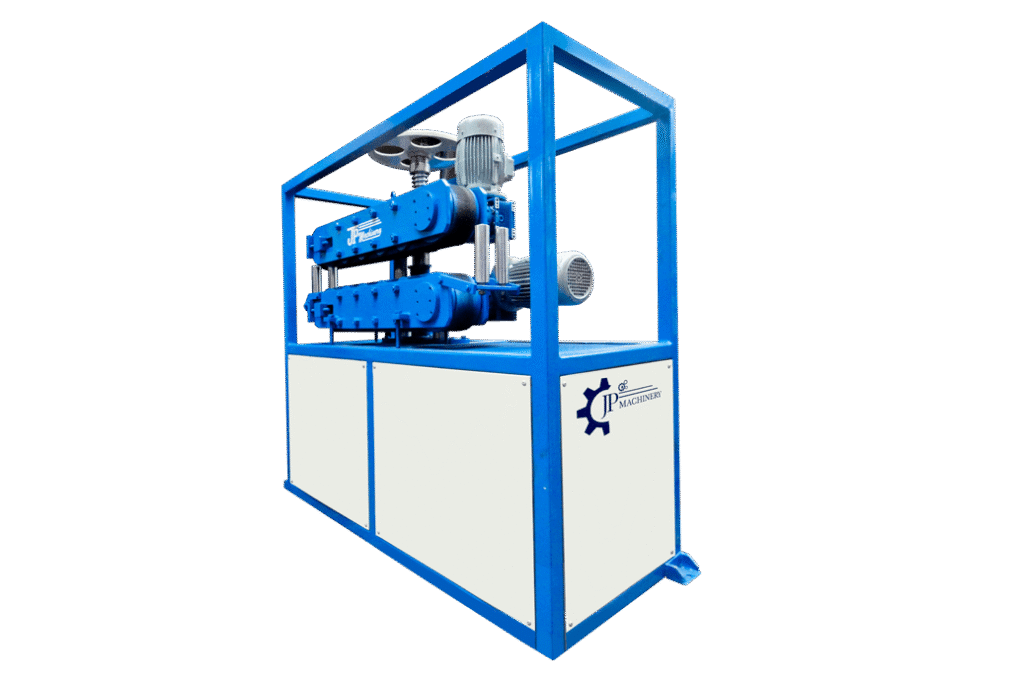

PVC Granule Extruder

Our 6-Inch PVC Granule Extruder is engineered for efficient and consistent production of high-quality PVC granules. Featuring a 6-inch barrel bore, this heavy-duty machine delivers an impressive output of up to 1200 kg/hour, making it ideal for large-scale compounding operations.

Designed for both rigid and flexible PVC formulations, the extruder ensures uniform melting, homogeneous mixing, and stable extrusion, resulting in granules with excellent consistency and flow properties. It’s equipped with a high-torque gearbox, energy-efficient heating system, and a customizable screw-barrel configuration tailored for optimal PVC processing.

Key Features

- Barrel Bore: 6 inches

- Output Capacity: Up to 1200 kg/hour

- Optimized for PVC granule production

- Precision screw design for uniform melt and mixing

- Durable gearbox and motor setup for continuous heavy-duty operation

- Efficient heating and cooling systems for temperature stability

- User-friendly control panel for easy operation and monitoring

Cable extruder line

Our Cable Extruder Line is a state-of-the-art solution engineered for the efficient insulation and sheathing of electrical wires and cables. Designed and manufactured in-house with precision, this machine ensures smooth operation, consistent output quality, and long-term durability.

Ideal for power cables, communication wires, and specialty industrial cables, our extruder line delivers unmatched performance and reliability for modern cable manufacturing.

Key Features

- Uniform insulation and sheathing

- Heavy-duty, durable build

- User-friendly control panel

- Efficient cooling system

- Customizable setup

- Suitable for power and communication cables

Box pasting machine

J.P. Machinery introduces an innovative box-pasting machine designed for efficiency, affordability, and ease of use in the wire and cable industry. Engineered to handle various box shapes and sizes, it features pneumatic cylinders and sensors for precise automation. With a compact design and simple adjustments, anyone can operate it effortlessly.

After extensive research and development, we have created a high- performance solution capable of pasting up to 500 boxes per hour, ensuring reliability and productivity.

Key Features

- Handles various box shapes and sizes

- Equipped with pneumatic cylinders and sensors for precision

- Compact and space-saving design

- Easy to operate with minimal training

- Quick and simple adjustments

- High-speed performance: up to 500 boxes/hour

- Reliable and low-maintenance operation

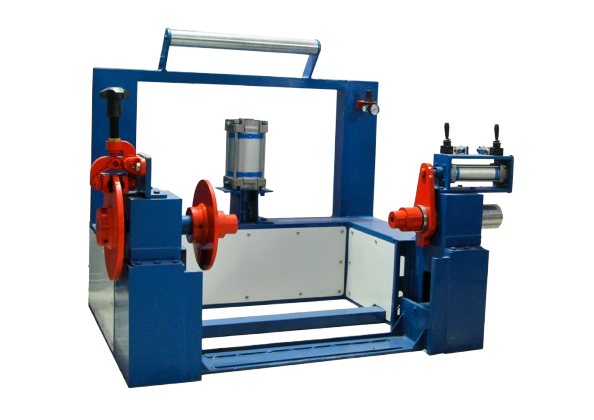

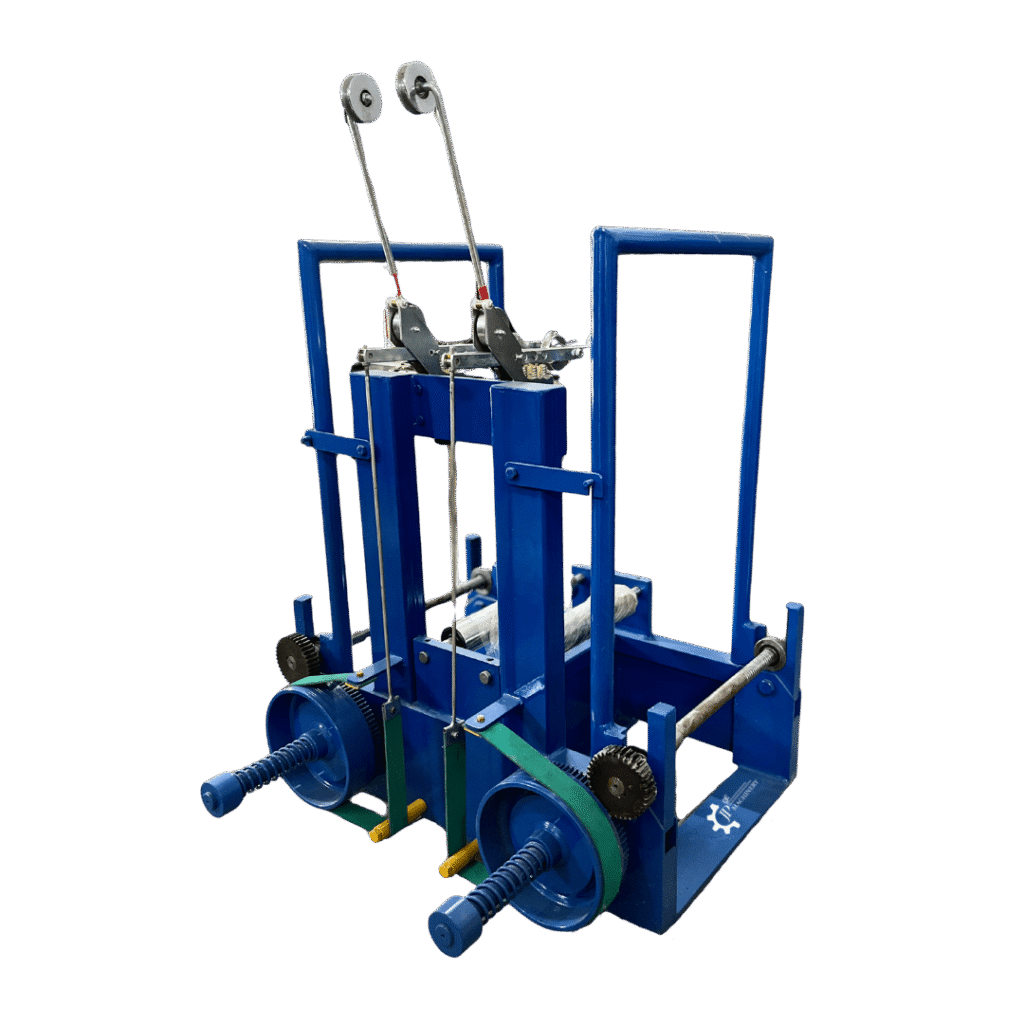

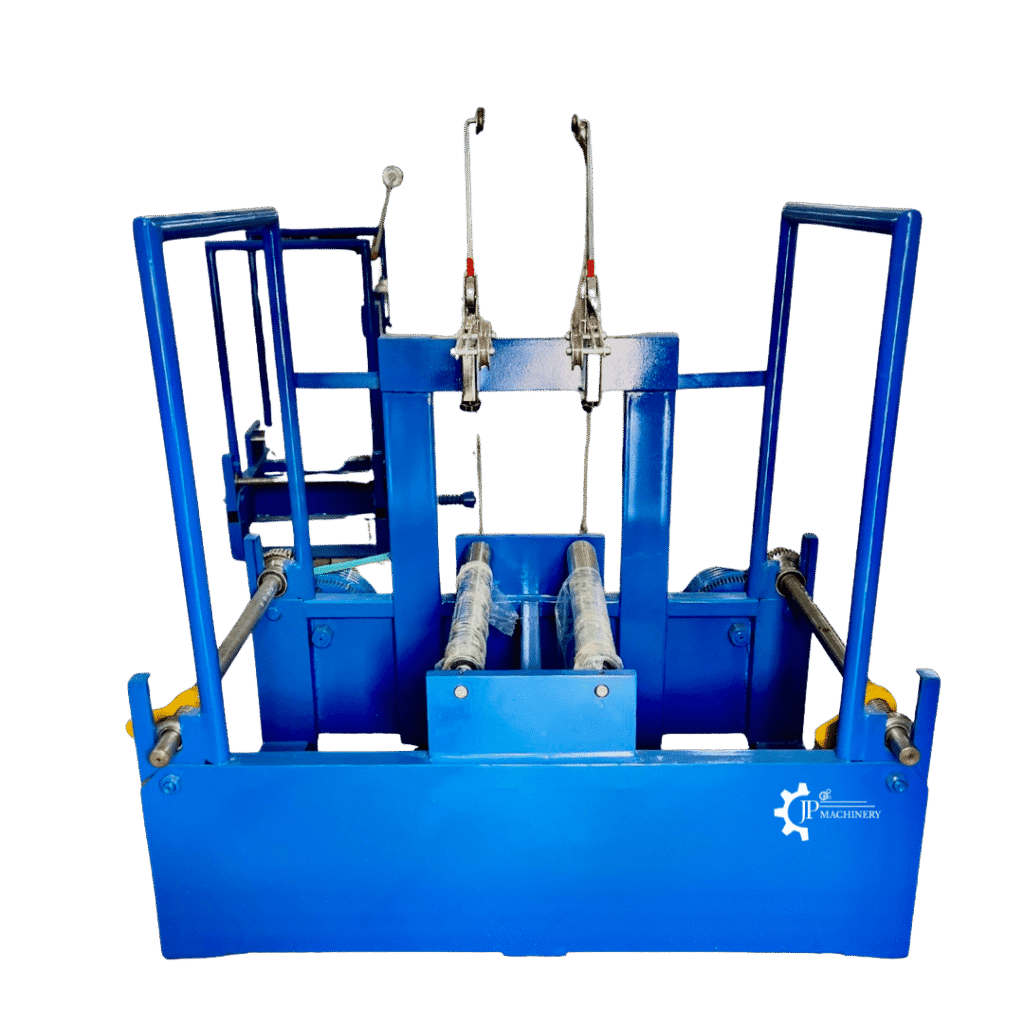

Dual take-up

Our Dual Take-Up is a specialized system with a bobbin size of 630mm and a winding speed of up to 12,000 meters per hour (for 1.5 sq. mm wire size). Designed to fit customer requirements and budgets, it ensures minimal downtime and reduced maintenance through the use of high quality components and advanced technology.

Like our standard take-up, this system functions independently of line controls, offering seamless adaptability to various production environments.

Key Features

- Suitable for 630 mm bobbin size

- High winding speed: up to 12,000 meters/hour (for 1.5 sq. mm wire)

- Operates independently of line controls

- Customizable to fit customer requirements and budget

- Minimal downtime with low maintenance

- Built with high-quality components for long-lasting performance

- Adaptable to various production environments

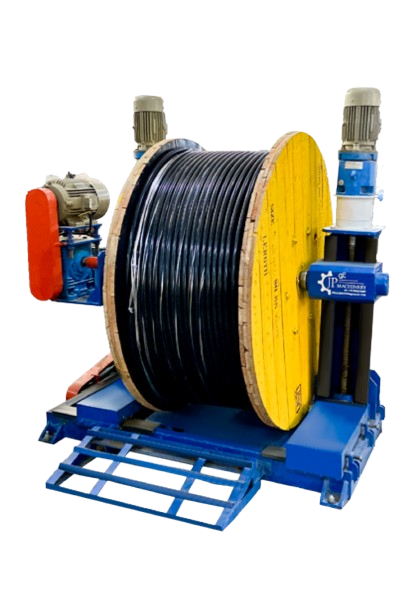

Pay-Off

J.P. Machinery offers a Pay-Off System with bobbin sizes ranging from 400 mm to 2200 mm (up to 20 tons), tailored to fit customer needs and budgets.

Our diverse range of pay-off solutions includes:

• Pneumatic Pay-Off

• Portal Pay-Off and Take-Up

• Dual Take-Up

• Column-Type Pay-Off and Take-Up

Each system is designed for optimal performance, ensuring smooth wire and cable handling across various production lines.

Key Features

- Supports bobbin sizes from 400 mm to 2200 mm (up to 20 tons)

- Wide range of models to suit different applications

- Includes pneumatic, portal, dual, and column-type systems

- Customizable to fit customer needs and budgets

- Smooth and efficient wire/cable handling

- Compatible with various production lines

- Built for reliable, long-term performance

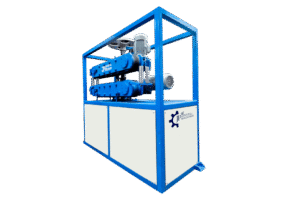

Mixer

Our High-Speed Mixing Machine is designed for a wide range of applications, including mixing, coloring, and drying various plastic and rubber materials. Built for durability and efficiency, J.P. Machinery’s mixers are known for their sturdy construction and reliable performance.

They feature compact designs, low energy consumption, and high efficiency, making them ideal for industries that require fast and consistent material preparation. The stainless steel blades ensure thorough and uniform mixing, delivering ready-to-use materials while maintaining production efficiency and safety.

Key Features

- For mixing, coloring, drying plastic and rubber materials

- Sturdy and durable construction

- Compact design with low energy consumption

- Fast and consistent performance

- Stainless steel mixing blades

- Safe and reliable operation

- Ideal for high-speed material preparation in industrial settings

Hopper loader

Our Hopper Loader is an advanced screw conveyor system designed for efficient bulk material transportation.

Ideal for transporting PVC granules and other powdered, granular, or small block materials.

Capstan

The Capstan is a motor-driven system designed for precise and synchronised wire and cable handling.

Its broad revolving cylinder enables consistent winding at variable speeds without requiring multi-speed gearboxes.

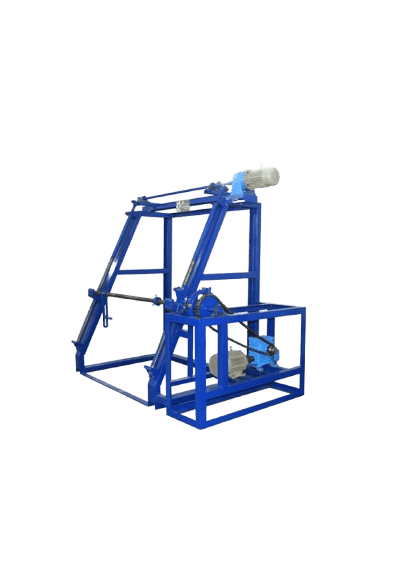

Column type Take-up

With years of experience in machinery manufacturing, we offer a Column-Type Take-Up designed for slow-speed and warehouse applications.

Engineered for safety and efficient material handling, this system minimizes floor space usage while ensuring superior performance.

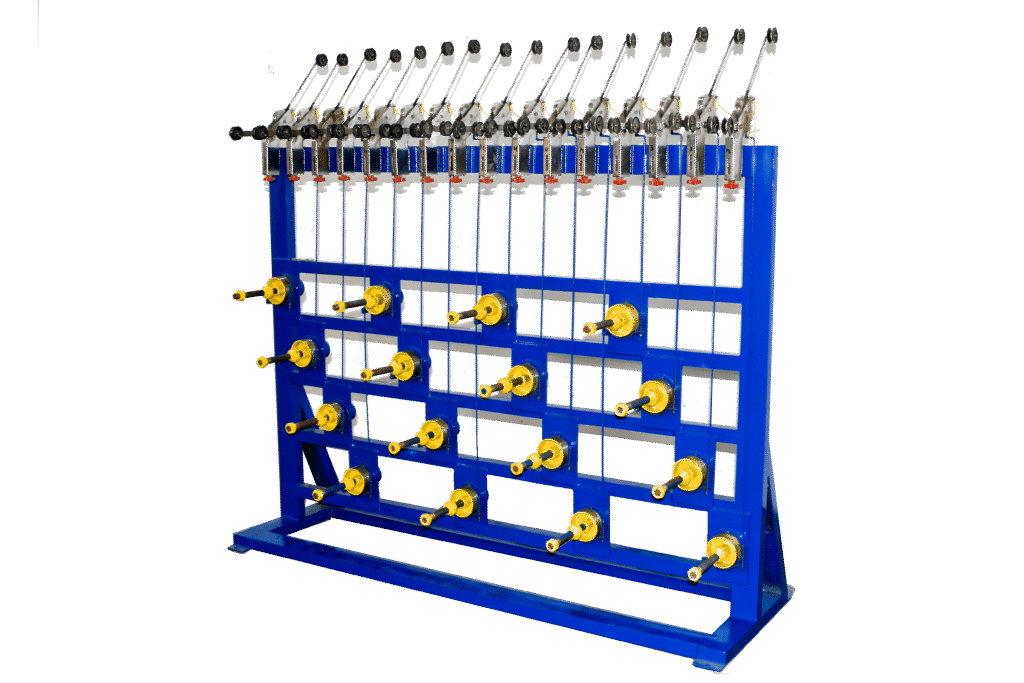

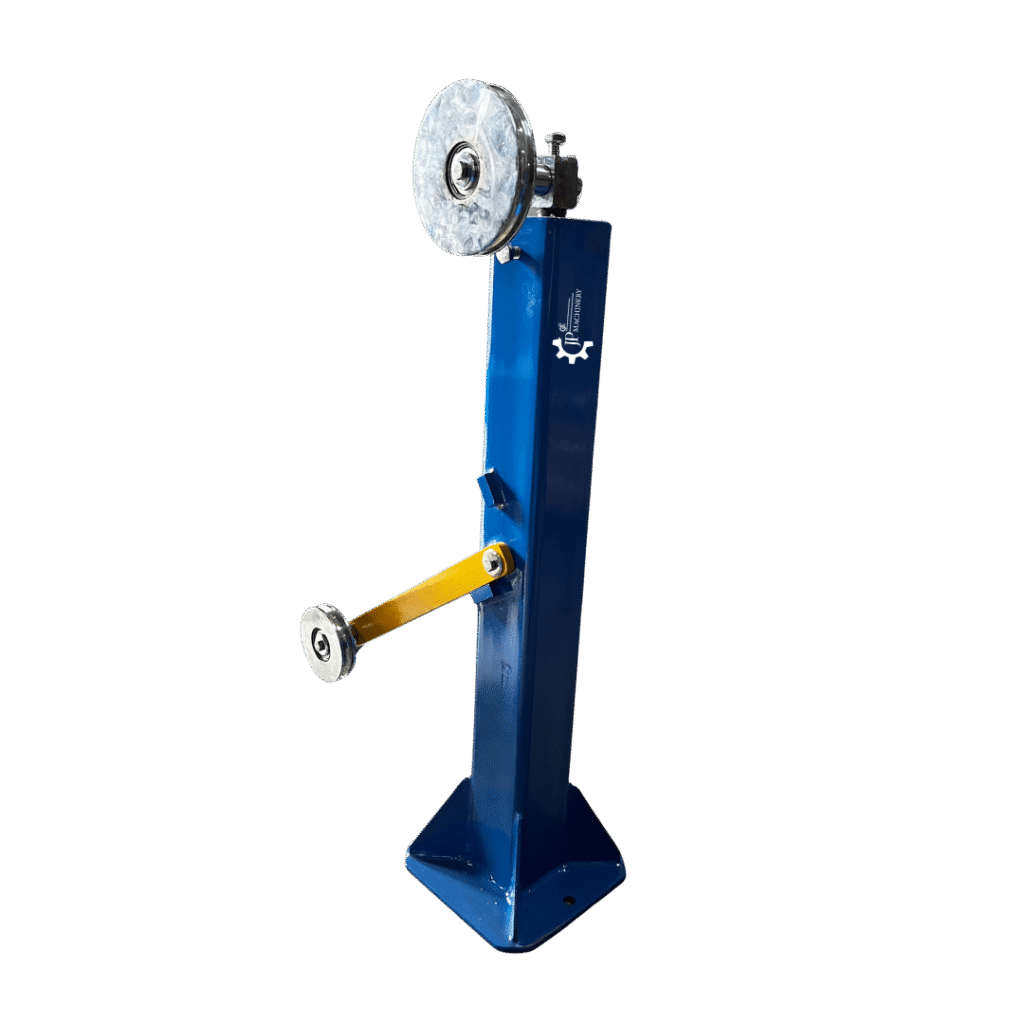

Copper Spool Stand

This Copper Spool Stand is a heavy-duty, precision-engineered structure designed to hold multiple spools of copper wire for easy unwinding during wire manufacturing or processing.

Ideal for use in cable manufacturing units and wire drawing plants, this stand enhances efficiency and organization in high-volume copper wire operations.

Cater pillar

Caterpillar designed for efficient material conveyance while occupying minimal space.

Engineered to meet customer requirements and budgets, this machine ensures smooth operation with minimal downtime and maintenance, thanks to carefully selected components and modern technology.

Pay-Off A type

Pay-Off System with bobbin sizes ranging from 400 mm to 2200 mm (up to 20 tons), tailored to fit customer needs and budgets.

Each system is designed for optimal performance, ensuring smooth wire and cable

handling across various production lines.

400MM REWINDER

This Copper Spool Stand is a heavy-duty, precision-engineered structure designed to hold multiple spools of copper wire for easy unwinding during wire manufacturing or processing.

Ideal for use in cable manufacturing units and wire drawing plants, this stand enhances efficiency and organization in high-volume copper wire operations.

630MM REWINDER

Caterpillar designed for efficient material conveyance while occupying minimal space.

Engineered to meet customer requirements and budgets, this machine ensures smooth operation with minimal downtime and maintenance, thanks to carefully selected components and modern technology.

TENSION CONTROL STAND

Pay-Off System with bobbin sizes ranging from 400 mm to 2200 mm (up to 20 tons), tailored to fit customer needs and budgets.

Each system is designed for optimal performance, ensuring smooth wire and cable

handling across various production lines.